Do you specialize in metal roofing, siding, trim, and accessories? CIDAN Machinery offers innovative, efficient, and flexible machinery to help you keep up with the latest trends in the architectural metal and roofing industries.

View Machinesin Architectural metal and roofing-

Architectural metal and roofing

-

Industrial fabrication machinery

Compliment your forming department with reducing operators and increasing part through put with semi-automated and automated folding machines!

View Machinesin Industrial fabrication machinery -

Sign manufacturing

For mass production or detailed custom pieces, our unique features will offer maximum flexibility and minimal setup time between jobs!

View Machinesin Sign manufacturing

News

-

ISA International Sign Expo Orlando, FL

March 7, 2024

Visit CIDAN Machinery at the International Sign Expo in Orlando, Florida, at Booth 2370, where…

-

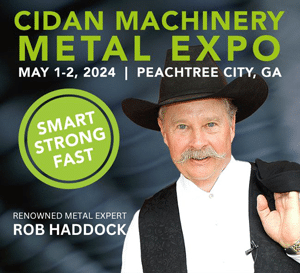

CIDAN MACHINERY Metal Expo (CMME) 2024

March 4, 2024

Join Us at CMME 2024: A Convergence of Innovation and Collaboration Prepare for an unparalleled…

-

Goat Gifts for Empowerment!

December 21, 2023

Goat Gifts for Empowerment! This holiday season, we are embracing the spirit of hope and empowerment. Our…

-

Revolutionize your sheet metal processing!

November 3, 2023

We are thrilled to introduce four smart innovations that are set to transform the sheet…

-

XTAP and XSPACE: Groundbreaking Features Enhancing Precision and Flexibility

February 1, 2022

CIDAN Machinery Group, the global leader in sheet metal folding solutions, is proud to announce…

-

MetalTalk with Guest, Chandler Barden, President of Cidan Machinery

March 16, 2023

In this MetalCoffeeShop™ MetalTalk episode, Heidi J. Ellsworth welcomes Chandler Barden of Cidan Machinery to…

History

CIDAN Machinery has been manufacturing machines since 1907, becoming a well-established leader within the sheet metal machinery industry. CIDAN’s history started with the founding of Göteneds Mekaniska Verkstad in Götene, Sweden in 1907. The company has now expanded to multiple parts of the world including Denmark, North America and Asia.

Read more